Biz zanglamaydigan po'latdan yasalgan quyma, investitsiyalarni quyish bilan boshdan kechiramiz. Zeninersiz po'latdan yasalgan qotishmani kuchaytirish bilan biz konservativlar, oziq-ovqat va sut, texnik, elektrotexnika, neft, energetika, elektr, energetika, energiya, energiya, energiya, energiya, energiya, energiya, energiya buyumlari uchun komponentlar bilan ta'minlaymiz aerokosea, suv osti kemasi va boshqalar. Sizga yuqori sifatli po'latdan yasalgan quyruqli quyishlarni ishontirishimiz mumkin. Zanglamaydigan po'latdan yasalgan quyruq qismlarining o'lchamlari 1 mm-800mm dan. Zanglamaydigan po'latdan yasalgan quyruq qismlarining og'irligi 50 funtgacha. Oddiy bardoshlik ± 0,01mm .

Biz arzon temir quyma mahsulotlar bilan eng zarur bo'lgan xususiyatlar bilan ishlab chiqarilishi mumkinligini ta'minlash uchun mijozlarimiz bilan ishlaymiz. zanglamaydigan po'latdan o'tkazish uchun qobiq. Bir kuni mum shakllari yaratilganda, ular qatlamli qobiqni shakllantirish uchun skurry va qumga botib, skurry va qumga solingan, so'ngra eritilgan zanglamaydigan po'latdan ham almashtirilgan.

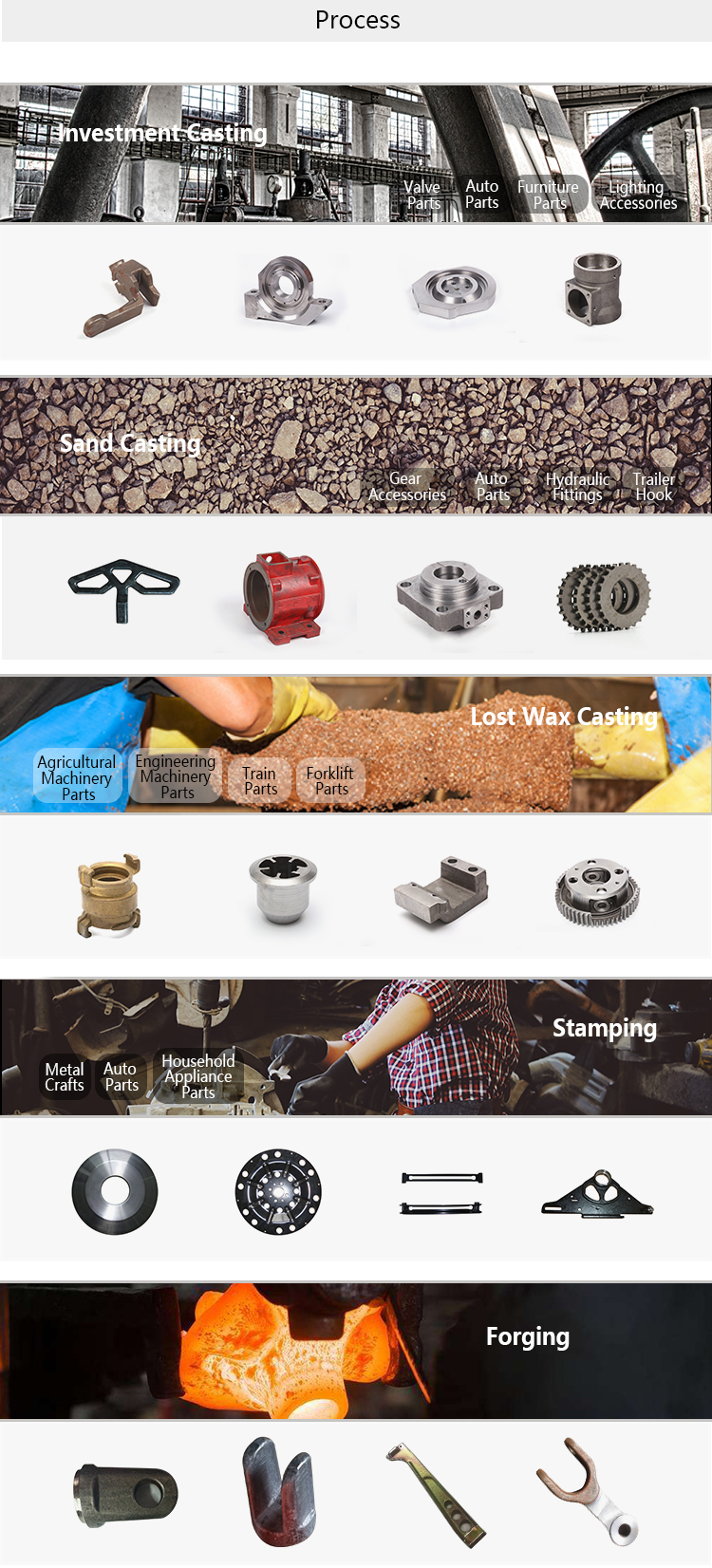

Qanday mahsulot turlarini taklif qilishimiz mumkin?

|

Products

|

According to the customers'technical drawings or s amples

|

|

Casting Material

|

stainless steel;SUS304;SS316;SS316L;17-4 PH

|

|

QT400-18,QT450-10,0T600-3QT700-2,FCD400,FCD450,60-40-18,65-45-12,ect.

|

|

Casting Product Weight

|

available from 0.02kg to 3000kg

|

|

Surface Treatment

|

Oxidation

|

|

Plating zinc

|

|

Painting

|

|

Hot galvanized

|

|

Powder coating

|

|

Electroplating

|

|

Sand blasting

|

|

Electrophoresis

|

|

Vbration Grinding

|

|

Inspection

|

*100% ins pection before shipping, offer the material reports and mechanical property reports

|

|

*Control Plan and PPAP documents according to the clients'requirements

|

|

*ISO9001: 2015 quality control system

|

|

Extra Service

|

CNC machining servce in our machining workshop

|

|

Advantages

|

* The dimensions and outs ide shape are similar with investment casting

|

|

*The surface roughness is good from 2.5 to 25um(100 to 1000um

|

|

*The min thickness can meet 3 mm(0. 120inch)

|

|

*decrease the internal crack and keep close structure

|

|

*As no joint and defect the cleaning and machining work can be less

|

|

*it's cheaper because its a simpler process and the foam is cheaper than the wax

|